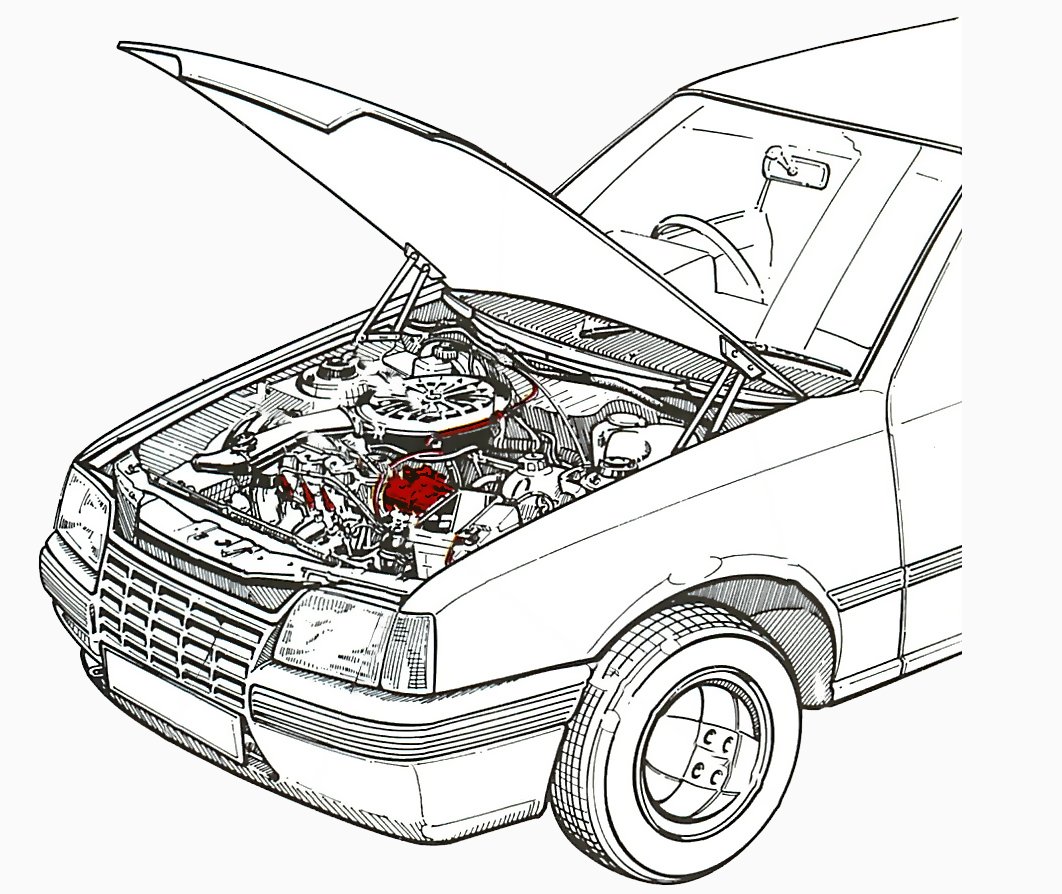

It's annoying enough being stranded at the roadside when the engine packs up, and matters are made worse if you don't know what the problem is. But it could be that something fairly minor has gone wrong, which you can easily put right when you've found the cause.

Engines usually stop suddenly only if they suffer from a lack of fuel or sparks. An engine that stops dead without prior warning has probably had a sudden ignition failure - although if it locks solid it's more likely to have seized.

A slower, spluttering halt, on the other hand, probably indicates fuel problems - ignition faults that cause similar poor running are unlikely to stop the engine in the short term.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

Systems checks

You can make a quick check on whether the ignition system is working by pulling off one of the HT leads at the plug and either resting the metal end connector within 6mm of the engine block, or inserting a spark plug and resting that against the block instead. If you can't do either, insert a piece of metal into the cap and rest that near the engine block. Get a helper to crank the engine over on the starter motor - if the ignition system is working properly, blue sparks will jump the gap.

To check whether the fuel is flowing, disconnect the fuel pipe at the carburettor and see if fuel gushes out when the pump runs. It is best to aim the pipe into an old jar when doing this, but if you can't find one just point the pipe at the ground, keeping it well clear of the hot exhaust pipe and any electric cables. To run an electric pump, all you need to do is get someone to turn on the ignition, but to operate a mechanical one you need to crank the engine over on the starter.

Both types of pump should deliver • a strong flow of fuel, normally at the rate of a few squirts of fuel every second.

Fuel problems

Check the flexible hoses for leaks and splits. Tighten the hose clips if any have come loose.

Check fuel flow by removing the fuel pipe from the carburettor and turn the engine over on the starter.

If the float chamber is flooding, tap it with a screwdriver handle to reseat the needle valve.

If a mechanical fuel pump has come loose, retighten it removing gaskets or spacers as necessary.

Mechanical fuel pumps do not usually fail without warning: more commonly, the fixings loosen off and the pump moves away from the engine slightly so that the pump's lever cannot achieve its full stroke and fuel delivery is greatly reduced.

If the pump is securely mounted but fuel delivery is a problem, you may be able to increase flow by removing some of the gaskets or spacers between it and the engine. Don't remove the thick spacer—this may lead to pump damage.

Electric pumps can suddenly stop working if their contacts become corroded. To check, listen with the ignition on for the pump ticking.

If there are no apparent problems but the car has run more and more badly until it has reached a standstill, remove the fuel filler cap. If there is a sharp rush of air when you do this, the vent is blocked —the pump cannot suck against a significant vacuum. You can get home by driving with the cap loose or by periodically removing the cap to vent the tank.

Ignition problems

Check for sparks at the plugs using a spare plug in the HT lead. Hold it against the engine block.

Replace a blown coil fuse with another, after checking for shorted out connections.

Make sure the points are opened by removing the distributor cap then rocking the car in gear.

If the ignition system is wet dry off excess water. Spray with water repellent if you have some.

If the engine stops dead, the chances are that the fuse (if one is fitted) protecting the ignition coil has blown. If the ignition light will not come on but most of the electrics work this is almost certainly the problem. You can substitute a fuse of the correct size from another, less vital component and carry on. But check first that the failure was not caused by a short circuit — a bare connector, for example — and insulate any suspect wires or connections with tape. Check also that the engine's earth strap has not become disconnected or split, as this will give similar symptoms.

In wet weather, a worsening misfire which eventually stops the engine is usually because of damp getting into the ignition components Dry the HT leads and the inside of the distributor cap thoroughly. If you have any water-resistant spray with you, give the parts a liberal coating once you have reassembled them.