Although car cooling systems are designed to maintain a fairly constant working temperature, the actual engine temperature can vary for a number of reasons. It may even reach such a high level that engine damage becomes a possibility.

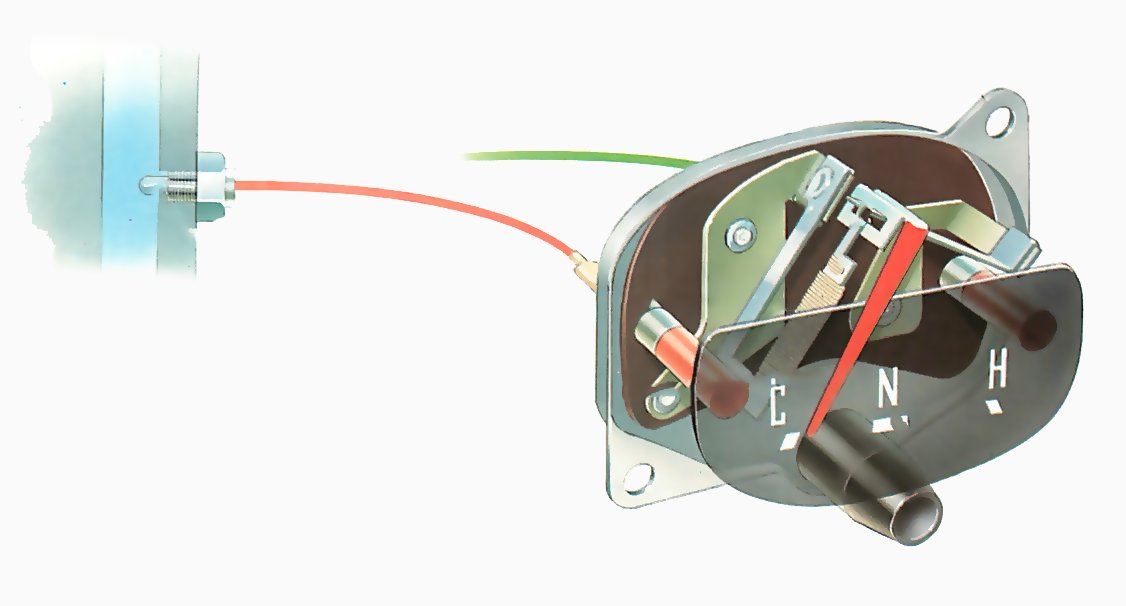

Bi-metallic strip gauges

Bi-metallic strip gauges creep up to their readings gradually when you switch on the ignition.

The sensor unit allows a current, varying with the engine temperature, through to a heater coil inside the gauge.

A bi-metallic strip inside the coil bends by an amount depending on the size of the current and deflects the needle across a calibrated scale to give a temperature reading.

The temperature gauge provides an early warning of overheating, allowing you to stop the car before any damage occurs. In very cold weather, the gauge can also tell you if the engine is being overcooled (which will increase fuel consumption and engine wear). You can then take preventative means, such as blocking off part of the radiator or changing the thermostat.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

The temperature measuring system normally consists of two elements; the gauge itself and the sensor unit that controls it, the two being connected by a single wire.

Types of gauge

There are two common types of gauge mechanism - magnetic gauges and bimetallic gauges. You can tell which type your car has by the way it reacts when you switch on the ignition. With magnetic instruments the needle immediately jumps to give a reading; bi-metallic gauges move slowly to the reading after being switched on.

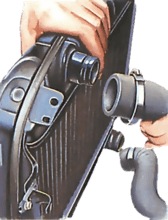

Temperature gauges are built into the car's instrument housing on the dashboard. The sensor unit, however, may be in one of several locations - the thermostat housing, the cylinder head or the upper radiator hose. In all cases the sensor is arranged so the coolant flows over it on the way out of the engine.

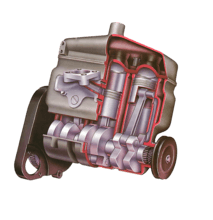

Magnetic gauges

Magnetic temperature gauges

The needle has a soft iron armature at its pivot, which moves by a certain amount depending on the strength of the magnetic field between the two wire-wound coils. The strength of the field depends on the size of the current passed into the coil from the sensor unit.

Magnetic gauges, also called moving iron gauges, have a pair of coils, one on each side of a pivoted iron armature that carries the needle. Sometimes the iron armature is weighted to hold the needle in the rest position; in other cases a light hairspring does this.

The coils are connected directly to the car's electrical supply - one is earthed direct and the other earths through the sensor, whose resistance varies with engine temperature. The current passing through the coils produces a magnetic field which moves the armature against the weight or spring. The amount of movement depends on the difference in the fields produced by the two coils. This difference varies with the size of the current let through by the sensor unit.

Bimetallic gauges

With bi-metallic strip gauges, the current allowed through by the sensor is fed to a coil of resistance wire wound around a bi-metallic strip that's linked to the needle.

Current flowing through the bimetallic strip causes the strip to heat up. As it does so it bends because the two metals in the strip expand with the heat by different amounts. The bending strip deflects the needle across the scale. The amount the strip bends depends on the amount of current arriving at the gauge, which in turn depends on the heat of the engine.

To avoid errors caused by variations in the car's supply voltage due to electrical load and generator speed, a voltage stabilizer is included in the instrument circuit. The voltage stabilizer also works on the bi-metallic strip principle and keeps the instruments supplied at a steady 8 or 10 volts.

Sensor units

There are two types of sensor units: the semiconductor type and the bimetallic strip type.

Semiconductor sensors are by far the most common type and consist of a semiconductor resistor element in a metal capsule. The resistance of the semiconductor decreases as the temperature increases. As the engine heats up, the sensor resistance reduces, increasing the current flow to the gauge and giving a higher reading.

The bi-metallic principle is used in a rarer type of sensor. Movement of a bi-metallic strip inside a heating coil in the sensor opens a pair of contacts, cutting off the current to the heater and the gauge. With the current off the strip cools and straightens out, remaking the contact so that current flows again. This sequence is repeated rapidly, with the amount of time the contacts are closed (and the amount of time that currents flows to the gauge) depending on the overall temperature of the sensor unit.

When the engine and sensor are hot, less electrical heating is needed to bend the strip and open the contacts and the cooling process takes longer. This means that the contacts remain open for longer so less overall current flows in the circuit. The needle is linked in such a way that a low current equals a high gauge reading.

This type of sensor has to be used with a bi-metallic strip gauge where the rapid on-off nature of the signal is smoothed out by the slow gauge response.