One of the most unnerving things that can happen in motoring is that you brake and one or more of the wheels locks up. This has two possible effects. It can make the car slew to one side or, if the car happens to skid in a straight line, the steering becomes useless and you lose all directional control.

Electronic anti-lock braking

Virtually all modern cars are fitted with microprocessor-controlled anti-lock braking systems (ABS). These can react very quickly to the wheels locking, interrupting and reapplying the brakes up to 25 times a second to ensure the vehicle doesn't skid.

The best way to prevent skidding is to apply a form of braking called cadence braking. A driver who is skilled at this can usually avoid wheel lockup, but an anti-lock braking system does the job automatically and usually more efficiently. More and more cars are now being fitted with such a system.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

How it works

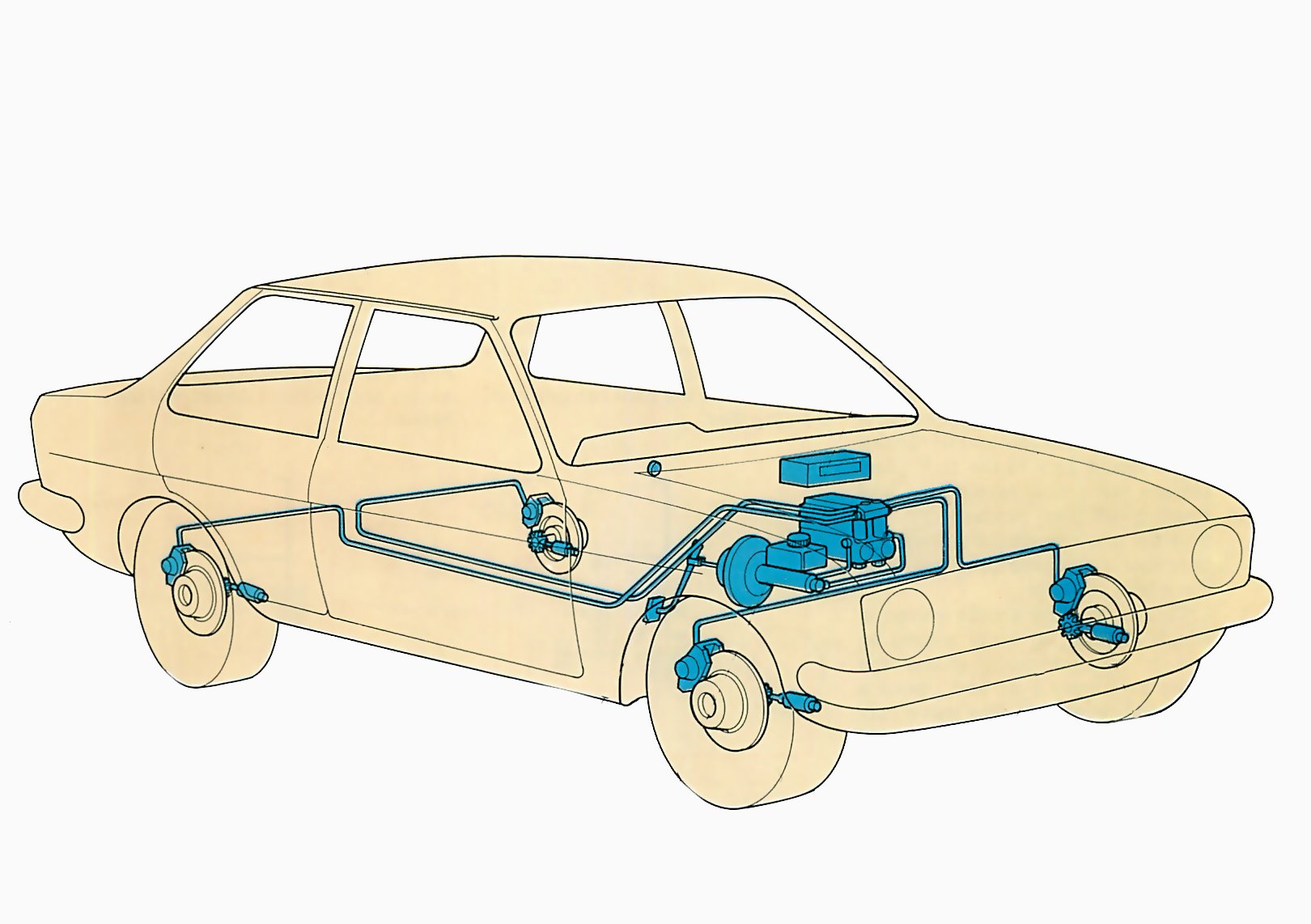

An anti-lock system automatically applies a form of cadence braking by detecting when a wheel is about to lock, releasing the brake at that wheel and then immediately reapplying it. The system, therefore, needs three main parts: a means of telling when a wheel is about to lock; a means of releasing its brake; and a means of restoring the pressure to the brake line after release.

The third feature is necessary because the anti-lock system has to work without the driver releasing and reapplying pressure on the brake pedal, and without the pedal sinking to the floor.

Skid detection

A car tyre provides its best grip just before it gives up altogether and slides. Any method of detecting a wheel about to lock must therefore allow for its speed falling slightly below the free-running speed - the system must not react too eagerly, but must still work quickly once the point of best grip has been passed.

In practice, there are two ways of detecting that a wheel is about to lock. Its speed can be compared with that of the other wheels, or the rate at which it is slowing down can be measured. In either case the hydraulic pressure at the brake can be released if the deceleration is too great.

Computer-based electronic systems work by speed-checking the wheels against each other, but usually run a double-check by keeping track of the rate of deceleration too. These systems are complex and relatively expensive. Some anti-lock systems use mechanical sensors that detect when a wheel is slowing too quickly.

Brake valves

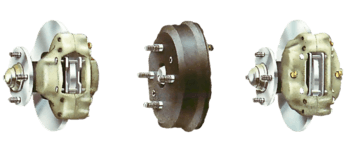

All anti-lock systems use some sort of valve to release the hydraulic pressure at the wheel cylinder to prevent the wheel from locking. The valve diverts the pressure back to the brake fluid reservoir. A simple release valve is not enough, however, because it would allow all the fluid from the master cylinder to flow back to the reservoir and the brake pedal would sink to the floor. Any release valve must have a means of shutting off the pressure supply from the master cylinder at the same time that it releases pressure from the wheel cylinder.

This is done by shuttle valves in which an internal body moves so that it simultaneously closes the pressure-supply port and opens a pressure-relief port. The valve may be moved by hydraulic control pressure or by an electromagnetic coil. Where the skid detector is a simple mechanical device, mechanical valves are usually used; with microprocessor systems the valves receive electrical control instructions.

Feed pumps

Any anti-skid system must include a pump, or pumps, to provide the pressure to reapply the brakes after they have been released without the driver needing to release and reapply the brake pedal. The pressure in an electronic system is stored in a tank called a hydraulic accumulator and controlled by a pressure regulator. In most systems the pump is electrically driven. It keeps the accumulator at sufficient pressure to ensure that the system can reapply the brakes often enough to stop in any circumstances.

Cars with fully powered hydraulics usually have a pump driven from the engine. These types of system are rare, though they have been successfully used on larger Citroen models for the past 30 years. The new Jaguar XJ6 also has such a system.

The mechanical system uses a purely mechanical pump close to, and driven by, each wheel. Each time the anti-lock system releases a wheel, the action of its running back up to 'free' speed generates enough pressure for the brake to be reapplied once more.

Electronic systems

These systems work at the rate of 15-25 on-off cycles a second. They detect the speed of each wheel by reading the speed of a smaller toothed disc attached to it. The disc runs through electromagnetic sensors that count the teeth to find out how fast the wheel is turning. The signals from the sensor are fed to a microprocessor which works out if any wheel is running more slowly than the others, or if any wheel is decelerating too quickly.

When the microprocessor decides it is time to release a wheel, it sends a signal to the electromagnetic valve to close off the pressure supply and momentarily release the existing hydraulic pressure. Then, when it senses that the wheel has speeded up enough, braking pressure is reapplied. The rise and fall in pressure is felt as a pulsing at the brake pedal — the only indication the system is in operation.

Lucas Girling SCS (stop control system)

Lucas Girling SCS (Stop Control System)

The SCS is entirely mechanical and only costs about a third of the price of ABS.

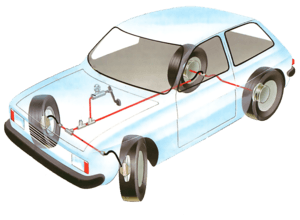

The hydraulic control units are driven by belts from the front drive shafts and use inertia sensors to calculate deceleration rates.

The control units incorporate simple plunger pumps to enable brake pressure to be reapplied once the wheel has been prevented from locking.

The SCS is entirely mechanical and only costs about a third of the price of ABS.

The hydraulic control units are driven by belts from the front drive shafts and use inertia sensors to calculate deceleration rates.

The control units incorporate simple plunger pumps to enable brake pressure to be reapplied once the wheel has been prevented from locking.

Normal braking

When the wheel is in no danger of locking, the modulator unit's dump valve is closed and brake fluid is allowed through to the caliper at full pressure.

Wheel about to lock

If the wheel decelerates too quickly, the unit's flywheel over-runs it, moves sideways and allows the dump valve to open, relieving brake pressure.

Restoration of pressure

The wheel speed increases and 'catches up' with the decelerating flywheel, which moves back to close the dump valve. The pump restores pressure.

Anti-lock layouts

The most popular approach, seen in cars such as the Citroen CX with the ATE system or the Ford Granada and Jaguar XJS with Bosch ABS, is to control the braking of each front wheel but to handle the two rear wheels together, the rear brake pressure being governed by whichever wheel is closer to locking. This 'three channel' approach reduces costs while sacrificing little in the way of effectiveness compared with systems that control all four brakes separately, such as that in the S-class Mercedes.

Honda adopt a slightly different approach for their ALB system, which works in much the same way but assumes that the most important wheel to prevent from locking is the most heavily loaded front one.

Mechanical systems

Mechanical ABS systems

The Lucas Girling SCS was recently introduced as an anti-lock option on Ford's front-wheel-drive Escort and Orion, although the system is suitable for most light, front-wheeldrive cars. The system only senses when the front wheels are about to lock, although a reduction in pressure at a front wheel is coupled with a proportionally smaller reduction at the diagonally opposite rear one to keep the car straight.

The Lucas Girling SCS uses an inertia-type locking sensor, which operates the brake valves directly, and wheel-driven pumps. With this system, over-rapid deceleration of the wheel moves a weight against a spring to open a hydraulic control valve. Although SCS has a slower cycling rate than electronic systems such as ABS, it gives satisfactory results, especially in light, front-driven cars such as the Ford Escort on which it was introduced, and it is also much cheaper.