Foret

An electric drill is useful for drilling pilot holes when fitting parts such as an aerial. With the right attachments it can also be used for cleaning carbon deposits from the cylinder head, for enlarging or cutting holes, and for rubbing down and polishing bodywork.

You do not need an impact drill, but a variety of speeds is useful. A chuck size of up to 1/2in. (12mm) is usually large enough.

Twist drills. High-speed drills or bits for cutting through metal are available in imperial or metric sizes, and can be bought in sets. Useful sizes include 3, 6, and 8 mm. Choose sets carefully.

Tapered grinder/cutter. A tapered grinder or cutter can be used to enlarge a drilled pilot hole up to the maximum diameter of the grinder head. For aerial or wing-mirror holes, a head 19-22mm diameter is usually suitable.

Hole saw. A hole saw cuts a hole of one size only, a different saw being needed for each size of hole. Sizes usually range from 16-50 or 75mm. Blades may be short reach - with a 4mm cut - or long reach with a 14 or 22mm cut. Blades can be removed and changed.

Wire brushes and sanding and polishing discs. Wheel-shaped and cup-shaped wire brushes can be fitted for metal cleaning, also narrow brushes for decarbonising. Abrasive paper discs - 24, 40, 80 and 100 grit - can be used for initially rubbing off rust and paint from bodywork; the lower the number the coarser the grit. A flap wheel is a long-lasting abrasive wheel made with dozens of flaps of abrasive materials. Calico mops are useful for buffing and polishing bodywork, and can be fitted with lambswool bonnets for finishing to a high shine. Some fitments need a carrier and clamp.

A drill is a tool fitted with a cutting tool attachment or driving tool attachment, usually a drill bit or driver bit, used for boring holes in various materials or fastening various materials together with the use of fasteners. The attachment is gripped by a chuck at one end of the drill and rotated while pressed against the target material. The tip, and sometimes edges, of the cutting tool does the work of cutting into the target material. This may be slicing off thin shavings (twist drills or auger bits), grinding off small particles (oil drilling), crushing and removing pieces of the workpiece (SDS masonry drill), countersinking, counterboring, or other operations.

Drills are commonly used in woodworking, metalworking, construction and do-it-yourself projects. Specially designed drills are also used in medicine, space missions and other applications. Drills are available with a wide variety of performance characteristics, such as power and capacity.

Read more on Wikipedia

Cet outil est utilisé dans

The best way to treat a dent is to raise the metal almost to its original level, then to...

Si un trou dans la carrosserie se trouve pas dans une zone de support de charge, tel qu'une sect...

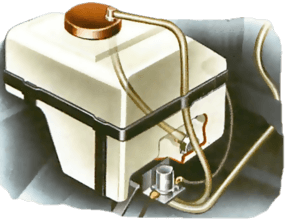

Cars with electrically operated windscreen washers sometimes have a switch controlling the motor...

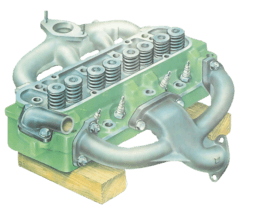

Good engine performance depends on valve condition. Worn guides or stems and burned or badly seat...