Vous pourriez avoir besoin de

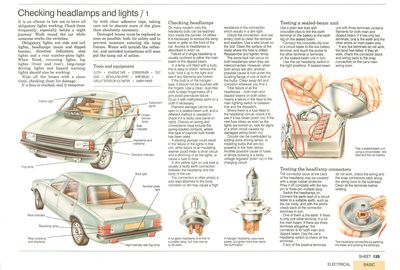

It is an offence in law not to have all obligatory lights working. Check them frequently, especially before a night journey. Walk round the car while someone works the switches.

Obligatory lights are side and tail lights, headlamps (main and dipped beams), direction indicators, stop lights and a rear number-plate light. When fitted, reversing lights, fog lights (front and rear), long-range driving lights and hazard warning lights should also be working.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

Wipe all the lenses with a clean cloth, checking them for damage.

If a lens is cracked, seal it temporarily with clear adhesive tape, taking care not to obscure more of the glass than absolutely necessary.

Damaged lenses must be replaced as soon as possible, both for safety and to prevent moisture entering the lamp fixture. Water will tarnish the reflector, and corroded connections will soon put the lamp out of action.

Checking headlamps

A tungsten headlamp is similar to a smaller lamp, but may use up to 45 watts.

On many modern cars the headlamp bulb can be reached from inside the bonnet; on others it is necessary to remove the lamp bezel or grille on the front of the car.

Failure of a single headlamp is usually confined to either the main beam or the dipped beam.

In a lamp unit fitted with a bulb, this is easy to check: remove the bulb, hold it up to the light and see if any filaments are broken.

A halogen headlamp uses more power, but gives more than twice the illumination.

If the bulb is of the halogen type, it should not be touched with the fingers. Use a clean, dust-free cloth to keep fingermarks off it and avoid premature failure. Clean it with methylated spirit on a cloth if necessary.

Filament damage cannot be seen in a sealed-beam unit, and a different method is needed to check if it is faulty (see panel on right). Checks on wiring and connections must include the spring-loaded contacts, where that type of bayonet bulb holder has been used.

A sticking plunger could result in the failure of the lights in that unit, while failure of an insulating washer could mean a short circuit and a dimming of all the lights, or cause a fuse to blow.

A dim yellow light on one side is usually a faulty earth connection between the headlamp and the body of the car.

The connection is often simply a wire lead attached to the body; corrosion or dirt may cause a high resistance in the connection which results in a dim light.

Unbolt the connection, and use emery cloth to clean the terminal and washers. Use a wire brush on the bolt. Clean the surface of the metal where the hole is drilled. Reassemble and tighten firmly.

The same fault can occur on both headlamps when they are interconnected. However, when both lamps are dim, another possible cause is rust under the locating flange of one or both of the bulbs. Clean away dirt and corrosion wherever you find it.

Total failure of all the headlamps - both main and dipped beams on both sides means a failure in the feed to the main lighting switch or between that and the dipswitch.

Where there is a fuse fitted in the headlamp circuit, check it to see if it has blown (See Working on the wiring system).

Circuits can be overloaded by adding extra driving lamps, or installing bulbs that are too powerful in the main lamps. Another possible cause of fuses or lamps blowing is a faulty voltage regulator (See How to test a car battery) in the charging circuit.

Testing a sealed-beam unit

Test a sealed-beam unit using a circuit tester, test lead and the car battery.

Use a plain test lead with crocodile clips to link the earth terminal on the battery to the earth tag on the sealed beam.

Connect the crocodile-clip end of a circuit tester to the live battery terminal, and touch the probe to the other terminal or terminals on the sealed-beam unit in turn.

Use the car headlamp switch in the right positions. A sealed-beam unit with three terminals contains filaments for both main and dipped beam; if it has only two terminals, one is the earth and the other works on main beam only.

If any live terminals do not work, the lamp has failed. If they all work, check the connector block and wiring back to the snap connectors on the cars main wiring loom.

Testing the headlamp connectors

Test headlamp connectors by earthing the tester and probing the terminals.

The connector block at the back of the headlamp may be covered with a large rubber protector. Prise it off complete with the two-pin or three-pin multiple plug.

Switch the headlamps on. Connect the earth lead of a circuit tester to a suitable earth, such as the car body, and with the probe check each of the connector terminals in turn.

One of them is the earth. If there is only one other terminal, it is for the main beam. If there are three terminals altogether, the connector is for both main and dipped beam. Use the car's headlamp switch to check all the terminals.

If any of the positive terminals do not work, check the wiring and the snap connectors back along the wiring loom to the bulkhead. Clean all the terminals before refitting.

Checking small bulbs

Types of car bulb

If one of the smaller lamps on the car fails to work, check whether the bulb is sound; if it is, check the fuse (See Checking and replacing fuses).

Never connect a plain test lead from a lamp-fitting terminal to earth. This will cause a short circuit and fuse failure. Always use a circuit tester or a voltmeter to test a fitting.

If the fault is in the bulb, usually it is possible to see a break in the filament, which may be accompanied by blackening of the glass.

There are many types of bulb in use — threaded types known as LES and MES; bayonet types with a centre contact (MCC and SCC); a bayonet type with more than one filament and more than one contact (SBC); and a wedge base or capless bulb which is used mainly for panel lighting, sidelights and number-plate illumination.

One of the later types is the festoon bulb, which is used mostly for interior lighting, but also in direction indicators and sidelights on some continental cars.

Obtain the correct replacement bulbs, as specified in the car handbook — the wrong bulb may not work properly or may not fit in the holder, and there are legal restrictions on the power of bulbs used for certain functions.

The SBC bulbs with double filaments used in brake lights have offset pins so that they can only be fitted the correct way.

If there is any doubt about a bulb, check by connecting it across the battery terminals. Use separate test leads from each terminal on the battery to the appropriate point on the base of the bulb.

If bulb and fuse are both sound, or if the fuse blows repeatedly, look for a loose or broken connection causing a short circuit, or a poor earth connection.

Testing small bulbs

Types of car bulb

To test a small bulb, connect a test lead from the earth terminal on the battery to the bulb stem casing, and touch the bulb's pole connection to the live terminal of the battery. Test a capless bulb by attaching two leads to the exposed wires on the glass casing.

If the bulb does not light, discard and replace it. Even if the filament appears to be intact, there must be a visually undetectable fault.

Testing bulb holders

Test a bulb holder by connecting a test lead from the holder to earth, and operating the switch.

To test a push-in removable bulb holder, remove the holder with its connected wiring from the back of the lamp fitting.

Test the bulb separately to make sure it is sound, and then refit it to the holder.

Connect a test lead from the holder to a suitable earth on the car body. Operate the switch to the light in question. If the light now works, while it did not previously, the lamp fitting in the car body is badly earthed.

The fitting may be earthed where it touches the body, or there may be a separate earth strap bolted to the body. Look for dirt, corrosion or loose connections. Clean and refit the earth connection, using a wire brush and emery paper.

Testing multiple clusters

Test a terminal in a multiple cluster by connecting a circuit tester to earth and probing the spring contact.

Many modern cars do not have separate bulb holders. All the lamps, particularly in the rear, and including sidelights, brake lights, reversing lights and turn indicators are clustered in a single fitting.

If a particular lamp in the cluster is not working, remove the lens to gain access to the bulb; remove the bulb and test it separately.

If it is good, clip the earth terminal of a circuit tester to a suitable earth on the car body and probe the internal contact spring in the lamp cluster. If the tester lights up, current is present at the connector and the problem is a poor earth on the lamp cluster.

To remove the cluster, first take out the other lamps to avoid damaging them. Undo the screws holding the cluster and withdraw it. Disconnect the lamp connections at the rear, making a note of where they go so that you can refit them in the correct position.