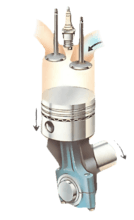

The compression tester usually screws in although some models have a rubber plug.

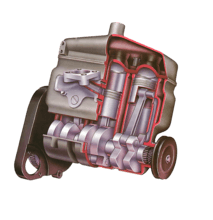

A good way to check engine wear is to test the compression of each cylinder using a compression tester, which you can buy or hire.

The check will reveal any leakage and enable you to detect whether the cause is worn piston rings, a blown cylinder-head gasket or a valve that is not seating properly.

Compression tester types

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

Test each cylinder in turn while the engine is being cranked by the starter motor, and then compare the pressure readings with each other and with the pressure specified in the car handbook.

Testing each cylinder

Run the engine until it reaches normal working temperature, then remove all the sparkplug leads. If there is a risk of getting the leads confused, label them.

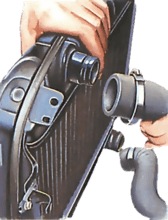

Remove the plug leads by gripping the caps, not by pulling on the leads which may damage them. Label the leads if necessary to avoid confusion when re-fitting them.

Remove the LT lead from the coil to avoid possible sparking at the plug caps. On a fuel-injection engine, disconnect the fuel-pump supply lead at the fuse.

Ask a helper to press the accelerator pedal hard down to open the throttle fully, and to be ready to turn the ignition switch to crank the starter.

Clean the area around the plug holes to prevent dirt getting into the engine. Remove the plugs with a plug spanner.

Remove a cylinder sparkplug and screw or push the connector of the compression tester into a sparkplug hole. If it has to be held in place, hold it firmly to avoid leaks.

Tell your helper to crank the engine for at least ten revolutions, or about six to eight seconds. Take care that loose clothing or hair does not get caught in belts or pulleys.

The pressure reading on the gauge.increases in steps, and may take up to ten revolutions to reach a maximum.

The compression tester usually screws in although some models have a rubber plug.

Note the pressure, and how many revolutions it took. Then test all the other cylinders, in the same way, noting the reading after the same number of turns.

The figures should be within 10 per cent of each other and of the maker's figure if the engine is in good condition.

If one or more cylinders give a lower result than the others, a further test (described in the next column) shows whether the leakage is past worn piston rings or elsewhere.

Compression tester adaptors

Plugs may have a long reach or a short reach, the length of the thread from the plug body to the nose. A tester with a screw connector has an adaptor which should be fitted when inserting the connector into the socket of a long-reach plug.

Tracing the fault

Pour about a dessert spoon (1 fl. oz or 10 ml) of clean engine oil into the suspect cylinder.

Reconnect the compression tester and crank the engine as described in the previous columns.

If there is a marked increase in pressure, the piston rings are worn. If not, either the bore is so damaged that the oil has failed to seal it or more likely — the gasket or valves are at fault.

To check the valves the cylinder head must be removed (See How to remove a cylinder head). A leaking gasket, however, will show other symptoms besides loss of compression. A leak between cylinders will cause rough running, and there may be a loss of coolant into the sump which will show as a white emulsification on the dipstick and a high oil-level reading.