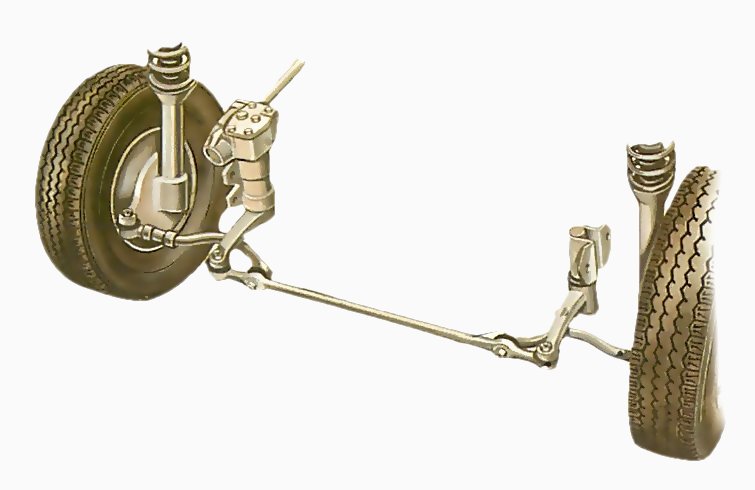

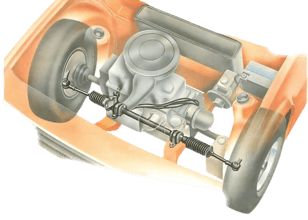

Steering-box system

In this steering-box system the joints on the track rod and track-rod ends are all ball joints.

The joints in a steering system all wear gradually and become slack. Because there are so many of them, and also because of the geometry of the system, a very small amount of play or looseness in the joints makes the whole system markedly sloppy and inaccurate.

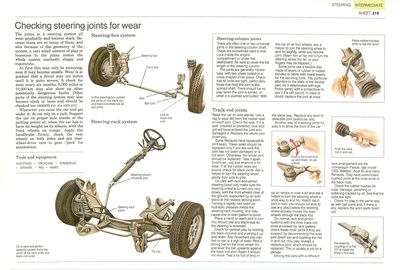

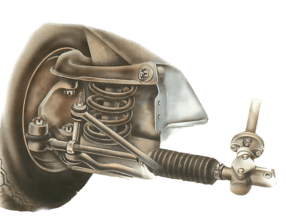

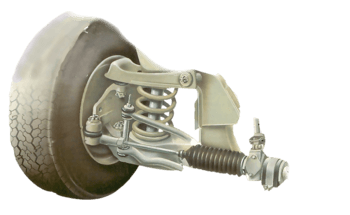

Steering-rack system

On a rack-and-pinion steering system there are joints at the rack ends and track-rod ends.

At first this may only be annoying; soon it may become unsafe. Wear is so gradual that a driver may not notice until it is quite severe. A check for wear every six months, 6,000 miles or 10,000 km may also show up other potentially dangerous faults. Other parts of the steering system may also become slack or loose and should be checked too (See Checking steering swivel pins).

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

Whenever you raise the car and get under it, do not rely on a jack. Support the car on proper axle stands at the jacking points or, when the car has to have its weight on its wheels, with the front wheels on ramps. Apply the handbrake firmly, chock the rear wheels on both sides and put rear-wheel-drive cars in gear (park for automatics).

Track-rod joints

Raise the car on axle stands. Use a rag to wipe dirt from the rubber seal on each joint. Check the seal. If it is split, cracked or perished, dust and grit will have entered the joint and damaged it. Replace the whole joint (See Replacing track-rod-end ball joints).

Push a track-rod end up and down, or use a lever.

Some old Renaults have replaceable joint-seals. These seals should be replaced only if you are sure the joint has not been damaged or is not worn. Otherwise, the whole joint should be replaced. Take it apart (See Refitting track rods and ball joints) and examine it for wear. If all the rubber seals are sound, check for slack joints. Ask a helper to turn the steering wheel gently from side to side.

Push the track rod out.

On cars with rack-and-pinion steering (See Checking rack and pinion steering), make sure the steering wheel is turned only very slowly, with the front wheels clear of the ground, supported by an axle stand at the nearest jacking point. Turning it rapidly can build up hydraulic pressure inside the steering-rack housing, and may cause one or both gaiters to burst.

Place a hand on each joint in turn. You should feel any slackness as the steering is reversed.

Check for vertical play by holding the track-rod-end and pushing it up and down. Any movement you can feel or see is a sign of wear. Rest a strong bar on the inner wheel rim, and lever the bar upwards against the track-rod-end. Again it should not move. Test a tie rod (if any) in the same way. Replace any wom or defective joint (See Replacing track-rod-end ball joints). Another way of checking joints for play is to drive the front of the car up on ramps or over a pit and ask a helper to turn the steering wheel a short way to and fro. Watch each joint in turn: you should be able to see any play before the steering wheel actually moves the road wheels through the track rod.

On normal rack-and-pinion systems with the inner track-rod ends enclosed by rack gaiters, check these inner joints if they are suspect by disconnecting the outer joint (See Checking rack and pinion steering) and pushing the rod in and out. Any play reveals a defective joint, which should be replaced. This is usually a job for a garage.

The steering coupling on a Fiat 127 is inside the drivers foot-well.

Among the cars with a different rack arrangement are the Volkswagen Passat, late model 1303 'Beetles', Audi 80 and many Renaults. They have unenclosed bushed joints at the inner ends of the track rods.

Check the rubber bushes for wear, damage, perishing or softening caused by oil. See that the bolts are tight.

Check for play in the same way as with ball joints and, if there is any, replace the worn parts (See Replacing other types of track rod).