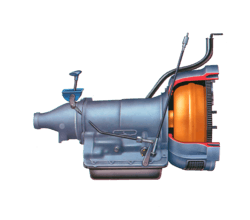

Convertisseur de couple

Vue d'un convertisseur de couple montrant la turbine et le réacteur.

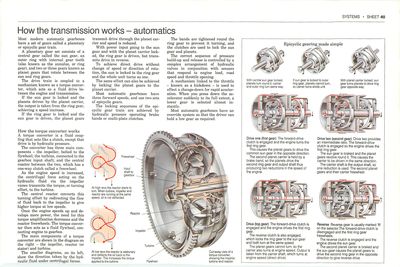

Most modern automatic gearboxes have a set of gears called a planetary or epicyclic gear train.

A planetary gear set consists of a central gear called the sun gear, an outer ring with internal gear teeth (also known as the annulus, or ring gear), and two or three gears known as planet gears that rotate between the sun and ring gears.

The drive train is coupled to a mechanism known as a torque converter, which acts as a fluid drive between the engine and transmission.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

If the sun gear is locked and the planets driven by the planet carrier, the output is taken from the ring gear, achieving a speed increase.

If the ring gear is locked and the sun gear is driven, the planet gears transmit drive through the planet carrier and speed is reduced.

With power input going to the sun gear and with the planet carrier locked, the ring gear is driven, but transmits drive in reverse.

To achieve direct drive without change of speed or direction of rotation, the sun is locked to the ring gear and the whole unit turns as one.

How a torque convertor works

À haut régime le réacteur commence à tourner . Lorsque, la turbine et le réacteur sont en cours d'exécution à la même vitesse, l'huile ne peut pas dévié.

À bas régime le réacteur est à l'arrêt et dévie l'huile de retour à la roue. Cela augmente le couple appliqué à la turbine .

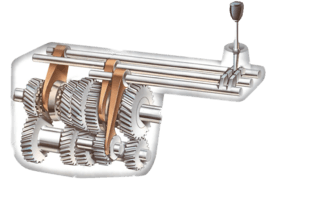

A torque converter is a fluid coupling that acts like a clutch, except that drive is by hydraulic pressure.

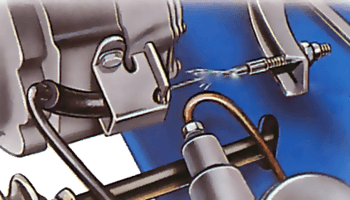

The converter has three main components - the impeller, bolted to the flywheel; the turbine, connected to the gearbox input shaft; and the central reactor between the two, which has a one-way clutch called a freewheel.

As the engine speed is increased, the centrifugal force acting on the hydraulic fluid via the impeller vanes transmits the torque, or turning effort, to the turbine.

The central reactor converts this turning effort by redirecting the flow of fluid back to the impeller to give higher torque at low speeds.

Once the engine speeds up and develops more power, the need for this torque amplification decreases and the reactor freewheels. The torque converter then acts as a fluid flywheel, connecting engine to gearbox.

The main components of a torque converter are shown in the diagram - the impeller, reactor (or stator) and turbine.

The smaller diagrams show the direction taken by the hydraulic fluid under centrifugal forces.

The same effect can also be achieved by locking the planet gears to the planet carrier.

Most automatic gearboxes have three forward speeds, and use two sets of epicyclic gears.

The locking sequences of the epicyclic gear train are achieved by hydraulic pressure operating brake bands or multi-plate clutches.

The bands are tightened round the ring gear to prevent it turning, and the clutches are used to lock the sun gear and planets.

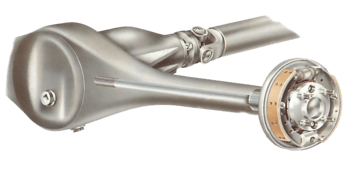

The correct sequence of pressure build-up and release is controlled by a complex arrangement of hydraulic valves in conjunction with sensors that respond to engine load, road speed and throttle opening.

A mechanism linked to the throttle - known as a kickdown - is used to effect a change-down for rapid acceleration. When you press down the accelerator suddenly to its full extent, a lower gear is selected almost instantly.

Most automatic gearboxes have an override system so that the driver can hold a low gear as required.