Vous pourriez avoir besoin de

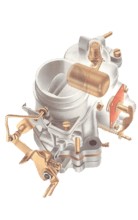

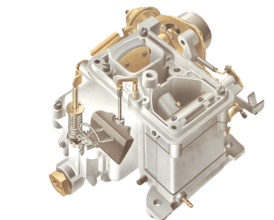

Ford carburettor for small cars

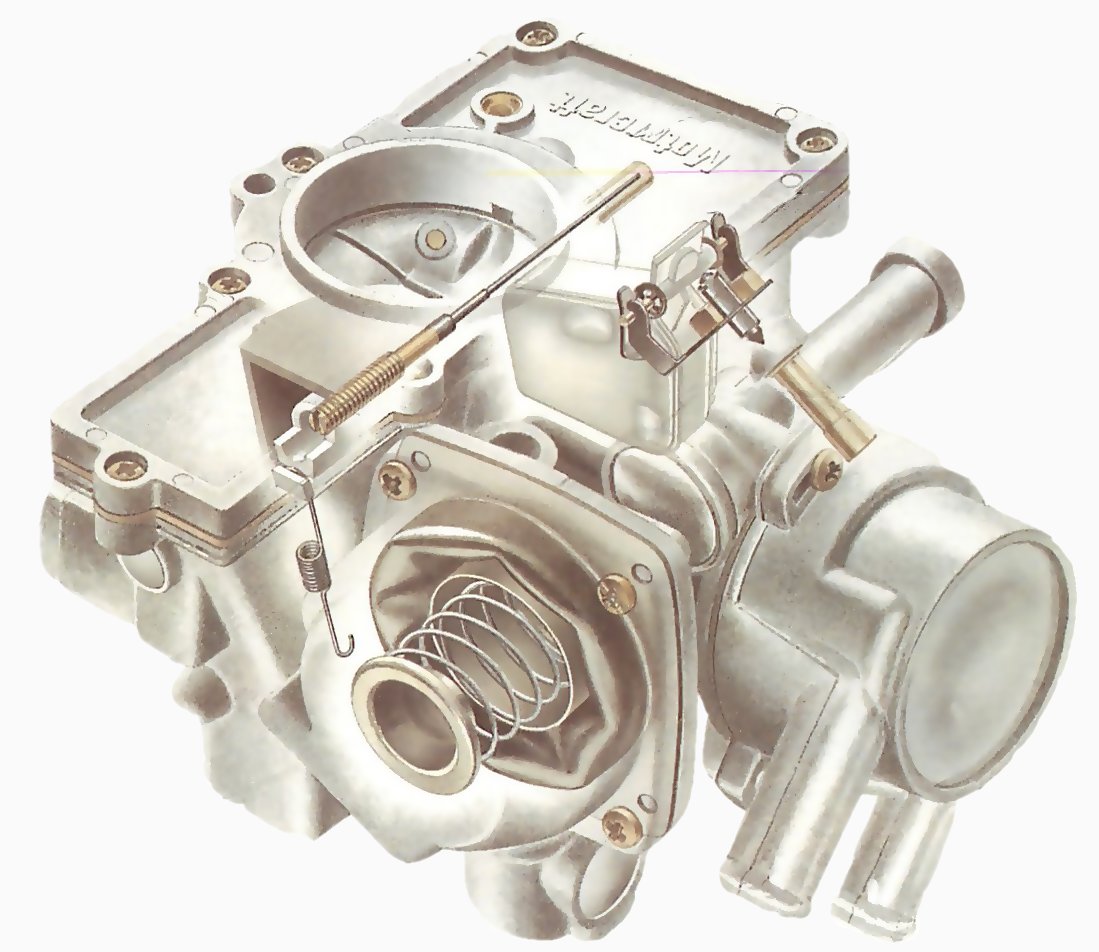

The carburettor combines the main features of the fixed-jet and the variable-jet types. It responds well to a yearly overhaul. No special tools are required.

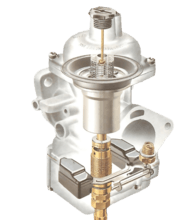

The Ford Variable Venturi carburettor is fitted to many small Fords.

It looks like an ordinary fixed-jet carburettor, and has some features typical of that type, such as an accelerator pump. However, its main mechanism is of the constant-depression type - like an SU, but tilted through 90 degrees.

Like any carburettor, it can become choked with dirt and sediment, and should be cleaned and checked about once a year.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

There are quite a few small, delicate parts, so prepare for this job as you would for a fixed-jet carburettor (See Checking and cleaning a fixed-jet carburettor).

Buy replacements for all the gaskets. You may also need to replace the main needle and jet and the float needle valve if they are worn, and the two diaphragms if they are damaged.

Remove the carburettor from the car for cleaning (See Removing a carburettor for cleaning), keeping it upright to avoid spilling fuel. Clean the outside before you dismantle it, to keep dirt out of the inside. Wash the parts in petrol and wipe them clean with a lint-free rag. Do not wash diaphragms - keep in a clean, dry place.

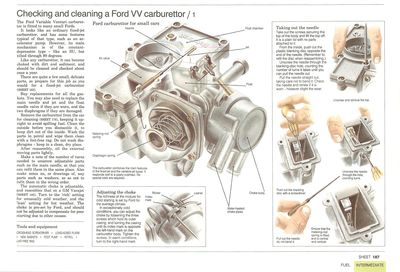

Adjusting the choke

The richness of the mixture for cold starting is set by Ford for the average climate.

In exceptionally cold conditions, you can adjust the choke by loosening the three screws which hold its outer casing, and turning the casing until its index mark is opposite the left-hand mark on the carburettor body. Tighten the screws. In warm conditions, turn to the right-hand mark.

After reassembly, oil the external moving parts lightly.

Make a note of the number of turns needed to unscrew adjustable parts such as the main needle, so that you can refit them in the same place. Also make notes on, or drawings of, any parts such as washers, so as not to refit them in the wrong order.

The automatic choke is adjustable, and resembles that on a GM Varajet (See Checking and cleaning a GM Varajet carburettor). Turn to the 'rich' setting for unusually cold weather, and the `lean' setting for hot weather. The choke is pre-set by Ford, and should not be adjusted to compensate for poor starting due to other causes.

Removing the jet body and needle

Take out the four screws holding the jet body - the block which houses the main jet. Lift out the jet body.

Check the jet carefully for wear. It tends to wear oval. If it is not perfectly round, renew it.

Checking the float and needle valve

Prise the float pivot out of its clips.

Prise the float pivot loose from its clips. Shake the float to make sure there is no fuel in it as the result of a leak. If it leaks, renew it.

Lift the float needle out of its seating.

Pull the float needle out of the valve and check both the needle and its seating for wear. A worn needle valve causes flooding and should be replaced.

Wash out the float chamber with a little petrol, and wipe it clean with a lint-free rag.

Freeing the diaphragm

Remove the four screws securing the diaphragm cover.

Remove the four screw holding the diaphragm cover. Take off the cover and the spring immediately under it.

Carefully peel the edges of the diaphragm free of the main carburettor body. Free the centre of the diaphragm by pushing off the circlip holding it, taking care not to nick the diaphragm.

Check the diaphragm, as you did that of the accelerator pump, and refit it carefully.

Remove the cover and spring; free the diaphragm edges.

Free the centre of the diaphragm by carefully easing off the circlip.

Check the diaphragm for holes or any other damage.

There is a small spring in the piston part of the air valve, inside the square aperture above and to the left of the diaphragm make sure that it is centrally placed and pointing upwards before refitting the top.

Removing the accelerator pump

Remove the three screws holding the pump cover.

Remove the three screws holding the cover of the accelerator pump. Take off the cover, which has a spring under it.

Carefully peel off the diaphragm, noting which is the outside and which the inside.

Lift off the cover and remove the spring.

Check the diaphragm for holes, cracks, perishing or wrinkles. Even a pinhole can spoil its operation. Fit a new diaphragm if necessary.

Peel off the diaphragm, noting which way it is fitted.

Also check that the jets under the diaphragm are clean. To clean them, remove and wash in petrol and blow through them with a foot pump.

Do not poke jets with wire or brushes — even a soft brush can leave a bristle in a jet and block it.

Make sure the diaphragm lies flat when refitting.